Detect Violations in Your Workplace, Monitor Restricted Areas, Unsafe Zones, and High-Risk Sections

Ensure Maximum Security and Efficient Operations with AI-Powered Restricted Area Monitoring

-

Seamless integration of marked zones and camera views

-

Instant alerts and live monitoring

-

Identify unauthorized access and predict high-risk operations in real-time

-

Achieve a risk-free environment

Application Areas:

-

Energy Transmission Lines or Power Generation Plants: Mark and define restricted areas to manage safe distances, minimize zone violations, and provide better monitoring.

-

Shipping/Maritime: Be more effective in monitoring cargo loading/unloading, vehicle traffic control, and pedestrian-vehicle interaction zones.

-

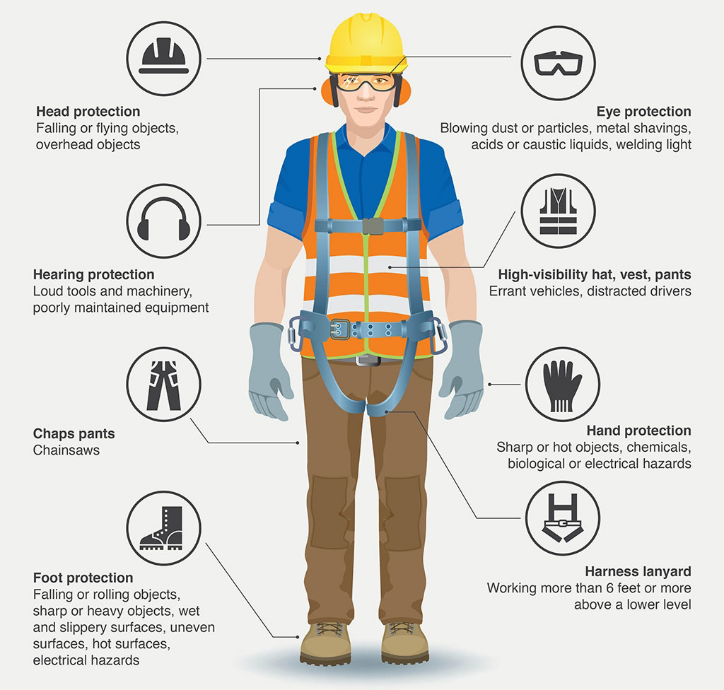

With UNICRON AI models integrated into your existing cameras, mark restricted areas to prevent personnel from entering hazardous zones, such as elevated work platforms and fall-risk areas.

High-Security Areas

By integrating UNICRON Vision AI solutions with your existing camera infrastructure, stop unauthorized movements around public or private sector sites. Implement control systems to prevent unauthorized personnel from breaching restricted areas, and identify zones where public and private businesses can operate in restricted or controlled spaces.