Real-Time Control with MES

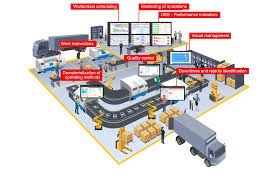

Manufacturing Execution Systems (MES) and digitization are transforming the manufacturing environment, enabling businesses to operate smarter, faster, and with greater transparency.

We offer a robust MES solution designed to optimize your operations and seamlessly integrate with broader digitalization strategies.

It monitors and manages manufacturing processes in real time and offers features such as:

- Production planning

- Job tracking

- Quality control

- Inventory management

By leveraging MES, manufacturers can optimize production workflows, shorten lead times, improve product quality, increase visibility, and identify bottlenecks.

We enable real-time data collection, automation of routine tasks, and informed decision-making processes by integrating digital technologies into every area of production, from the shop floor to supply chain management.

Key features of MES include:

- Data collection from workstations, employees, equipment, sensors, and materials.

- Real-time dashboards accessible via panel PCs and web applications.

- Integration of modules for production orders, workforce management, and OEE tracking.

- Instant data processing from IoT sensors and PLCs, with decision support systems.

MES Specifics:

- Smart touch industrial panels (available in various sizes).

- Ideal for strategic locations such as WorkCentre.

- Cost-effective digitization for old machines using IoT cards.

- Perfect for 24/7 operating devices like compressors.

- Combines advanced data collection with real-time panel interactions.

- Integrates with other modules to accurately calculate OEE and TEEP.

- Track production quantities from manual tasks in real time.

- Add buttons and switches for seamless interaction.

- Compatible with major PLC brands (Siemens, Schneider, ABB).

- Connects via Ethernet, Modbus, APIs, or OPC-UA.