Fabrikalarda güvenlik, hem çalışan sağlığı hem de üretimin sürekliliği açısından kritik bir öneme sahiptir. Geleneksel güvenlik önlemleri her zaman yeterli olmazken, görüntü işleme teknolojileri iş kazalarını önlemede devrim niteliğinde çözümler sunuyor.

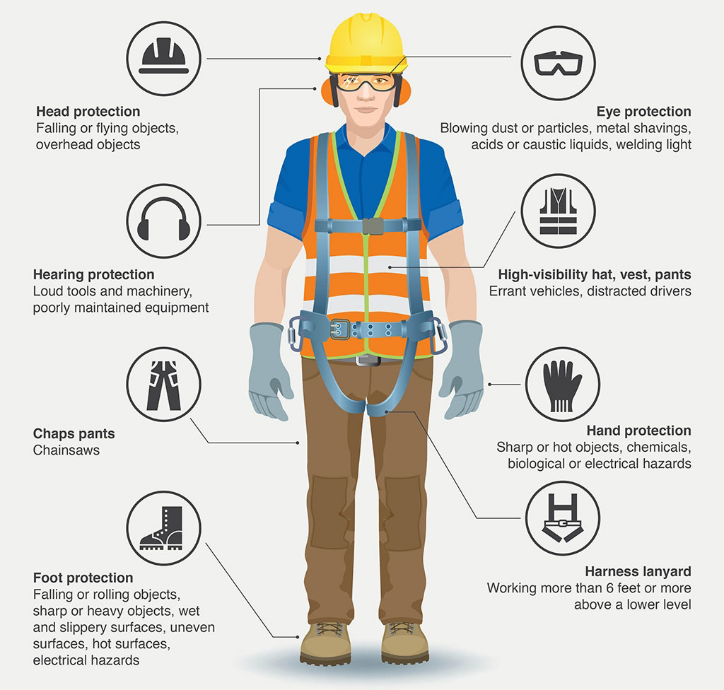

Yapay zeka destekli kameralar sayesinde KKD uyumluluğu tespiti yapabilir, çalışanların kişisel koruyucu ekipmanları eksiksiz kullanıp kullanmadığını kontrol edebilirsiniz. Forklift izleme sistemleri, fabrika içi trafiği optimize ederek kazaların önüne geçerken, sigara ve duman tespiti gibi sistemler yangın riskini minimuma indiriyor.

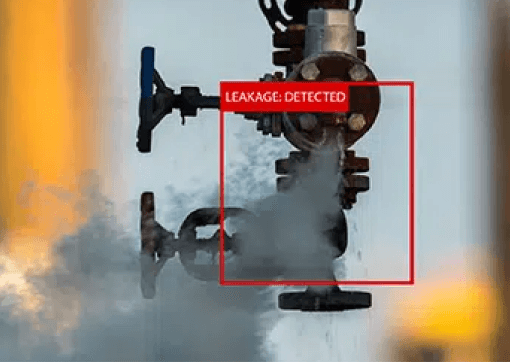

Görüntü işleme teknolojileri ayrıca, kayma ve düşme gibi kazaları anlık olarak algılayarak, müdahale süresini hızlandırıyor. Sınırlı bölge izleme sistemleri ile yetkisiz kişilerin kritik alanlara girişini engellemek de mümkün hale geliyor.

Bu teknolojiler yalnızca güvenliği sağlamakla kalmıyor, aynı zamanda işletmelerin iş sağlığı ve güvenliği standartlarına uygun şekilde faaliyet göstermesine yardımcı oluyor. Akıllı görüntü işleme sistemleri ile fabrikalarda sıfır iş kazası hedefi artık hayal değil!